A widely reported issue on the Glowforge has been failure of the flat flexible cable (FFC) that connects the main chassis to the lid.

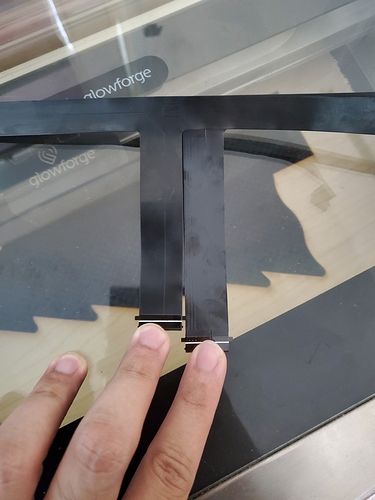

The FFC:

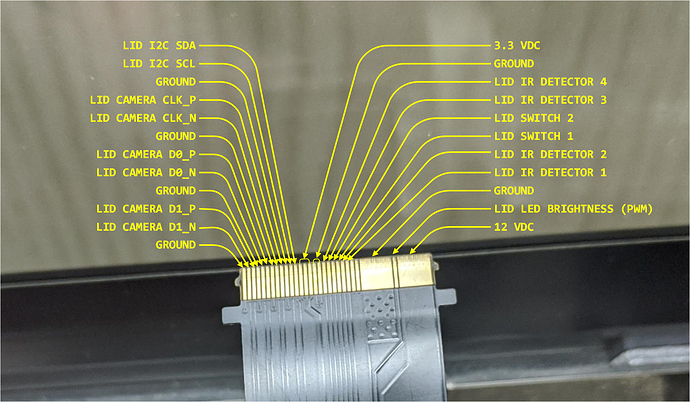

The FFC connects to a circuit board mounted to the rear of the chassis, which connects to another cable assembly that runs to the main control board (J4). This cable carries power, lid closure, LED brightness control, IR detector, I2C bus and lid camera signals.

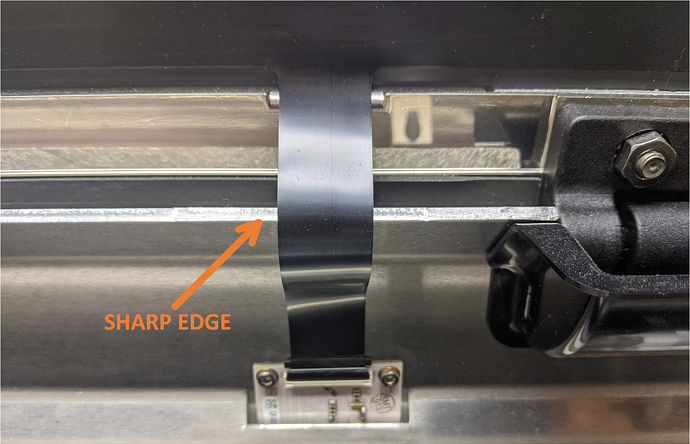

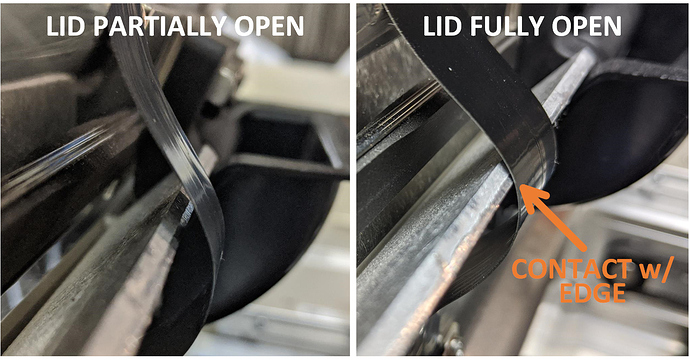

The problem with this cable comes down to a mechanical design issue. The cable runs near a sheared and somewhat sharp edge in the chassis.

The cable was not made long enough to avoid contact with the sharp edge when the lid is swung to its maximum open position.

Repeated contact with the sharp edge will eventually wear through the cable causing failure due to electrical shorts from contact with the grounded sharp edge, or due to breaks in the electrical traces.

Glowforge has been sending out replacement cables to impacted users (not sure if they are sending these for free to owners with out-of-warranty units). As usual, GF is tight lipped and it is unknown whether this design flaw has been remedied on later production units - I’d be interested to hear from owners of recently produced units.

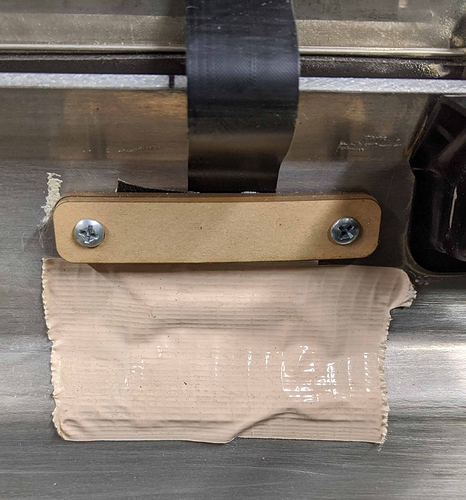

If the cable on your unit makes contact with this sharp edge, you can do a couple things to reduce the likelihood of failure. First, you can avoid opening your lid to its most upright position. Second, you can place a piece of duct tape over the edge behind the cable. I’d suggest being careful not place too thick of a barrier behind the cable, as this may cause mechanical stress on the connector and cause more problems…

If your cable has already failed, you are at the mercy of Glowforge. This cable is a spec part, and there are no generic replacements available.

For the curious, here’s what this cable carries: