Did a bit more digging. Looking at the information given by @ScottW514 in this thread, test point B2C is the “HV PWM”. Measuring this, I can indeed see the control board attempting to adjust the laser power. Following it through to the connector, this pin appears to connect to pin 13 of the ribbon cable going to the power supply (just found the wiki and confirmed this matches what Scott found). I removed and re-seated my ribbon cable and have confirmed that there is continuity all the way through to the power supply end.

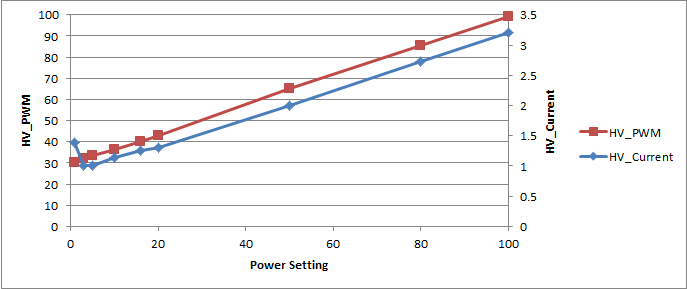

Looking even closer, I connected to B2F to observe the analog feedback of laser current. I performed a number of scores at various power levels and plotted the measured duty cycle and voltage corresponding to HV_Current (after settling, there is some initial overshoot). It appears that the HV current and duty cycle track each-other linearly from 100% down to about 5%. Below 5% the power supply current regulation appears to fall apart, turning into what is hopefully dithering but with an RMS value around 1.4-1.7V (depending on zoom level on the scope). I see this continuously at 1%, and intermittently at 3%. 5% power appears to be the lowest value that the power supply can regulate reliably.

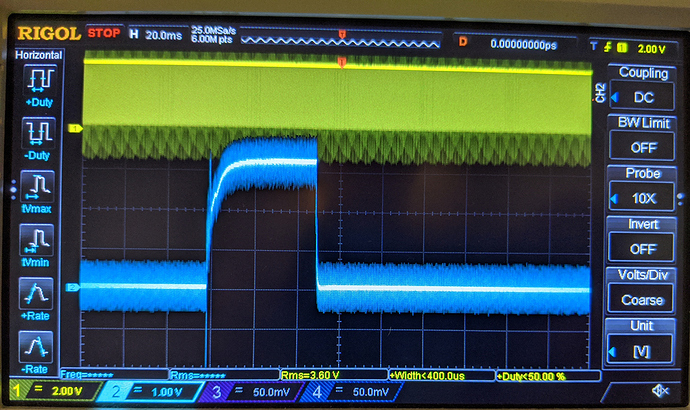

HV_Current at 100% power

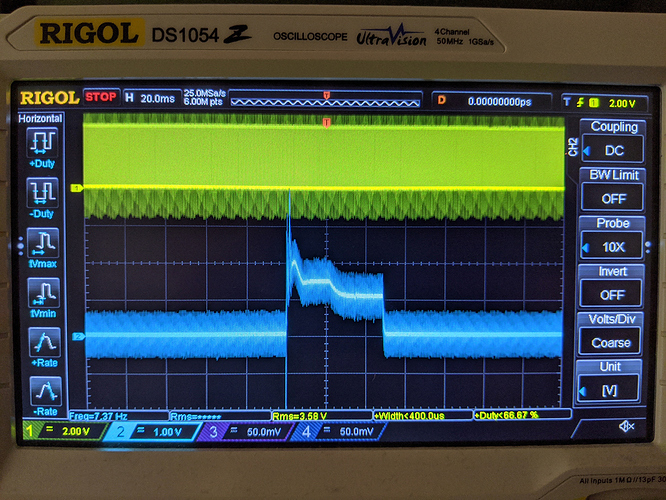

HV_Current at 5% power

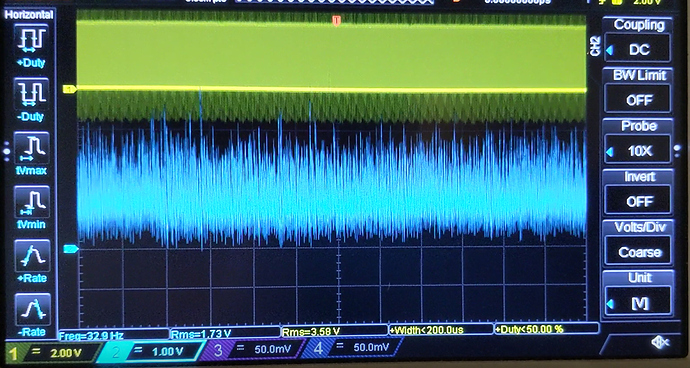

HV_Current at 1% power

Plot. HV_PWM is in % duty cycle measured at B2C and HV_Current is in Volts B2F.

So it looks like the PWM ranges from 30-99% as the power setting ranges from 1-100%. I’m assume that this is likely due to the minimum power required to make the laser “lase”, but I’m not sure. Does this mesh with the experience of others who have measured their units in action?

Overall, it appears that my power supply is working as expected. Assuming that 30% actually is the lowest power setting, my control board is also working as expected. So now I’m confused as to why I’m struggling to varying depth/intensity when I run engraves, scores, and the like. How come engraving a square on plywood with a power level of 1%, speed of 1000, and LPI of 225 results in a pocket 0.56mm deep, but power level 100%, speed of 1000, and LPI of 225 results in a pocket 0.96mm deep? I would expect that a power level of 1% at speed of 1000 would barely mark the surface. I can’t think of any other way to reduce the amount of energy delivered. Any thoughts? Am I doing something wrong?